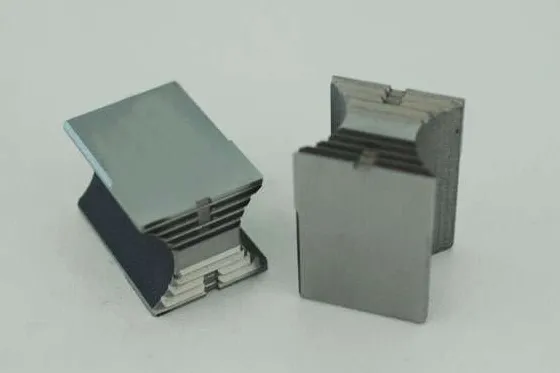

optical communication parts|Analysis of rust removal methods for precision parts

Precision parts processing or accessories, such as bearings, etc. due to inventory conditions or improper rust prevention, can basically not be processed by mechanical methods, and chemical pickling will damage the accuracy of the parts. Based on many years of processing experience, Jiamad Electronic Technology has summarized some methods for removing rust, which will not damage the workpiece, the parts will not change, will not be corroded, and the high-precision parts will be reworked or repaired. Next, let's talk about the specific rust removal methods for the precision parts of the communication cavity.

1. Soaking cleaning process

1 Add the professional cleaning stock solution to the tank (it is best to use a plastic or stainless steel tank, which can reduce the penetration of iron ions into the stock solution and reduce the service life);

2 Use electric heater to heat to 40-50 degrees and keep it, normal temperature can just need to extend the time;

3 Immerse the hardware processing parts into the tank;

4 If the power needs to be further increased, a circulating pump can be added to stir the tank liquid;

5 After the rust is completely dissolved, take out the workpiece and rinse with water-based anti-rust agent;

6 Naturally dry or dry after rinsing, or directly dehydrate and prevent rust;

7 When required, perform quan surface rust prevention and transfer to the next process.

2. Scrub cleaning process

1 Repeatedly scrub with a rag and mash, this method is suitable for cleaning and rust removal of large equipment or workpieces;

2 After scrubbing, dry it with hot air or apply anti-rust oil after natural drying.

The above is all the analysis on the rust removal method of the precision parts of the communication cavity, I hope it will be helpful to everyone.