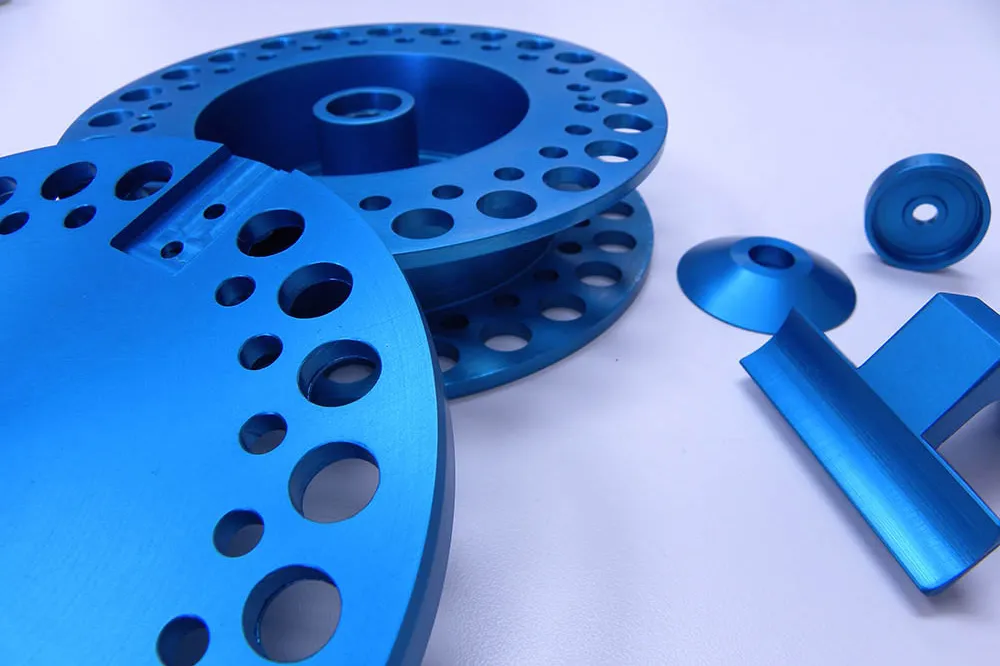

precision metal|Precautions for precision plating

Precision electroplating usually means that the original tolerance of the parts that need to be electroplated (oxidized) is small, generally within 0.01mm. Under the premise of meeting the product functionality, after electroplating (oxidation), the size of the parts can still meet the original tolerance requirements .

Everyone knows that due to the current effect of electroplating, there is a problem of uneven current density distribution on the surface of parts. Therefore, precision electroplating is not easy to achieve in actual production. In addition to strict control of the electroplating process, parts machining The cooperation is also essential. Specifically, if you want to achieve precision electroplating, you need to pay attention to the following items:

Choose the appropriate type of surface treatment. Purely considering the uniformity of the thickness of the coating, electroless nickel plating is the best. Good electroplating suppliers can control the thickness range of plus or minus 1 micron, but for some parts that are too precise, customers do not want any change in the thickness of the surface treatment. , Then some chemical conversion coatings can be used.

Choosing the right raw materials is particularly important in the anode reaction. For some precision assembly parts, customers want the same color, so all parts need to use the same grade of aluminum alloy material, and more strictly, the same grade and the same batch of raw materials from the same material supplier are required.

Appropriate plating margin must be reserved. In many cases, in order to meet the anti-corrosion requirements, a certain plating thickness must be electroplated. If the margin is not reserved before electroplating, the size of the part will inevitably exceed the expected size.