Complete seven crafts in one go, go scheming|precision medical parts

The core machine is a kind of precision processing equipment, which can complete the compound processing of turning, milling, drilling, boring, tapping, and engraving at the same time. It is mainly used for the batch processing of precision hardware and shaft special-shaped non-standard parts. Features such as complex structure and multiple batches.

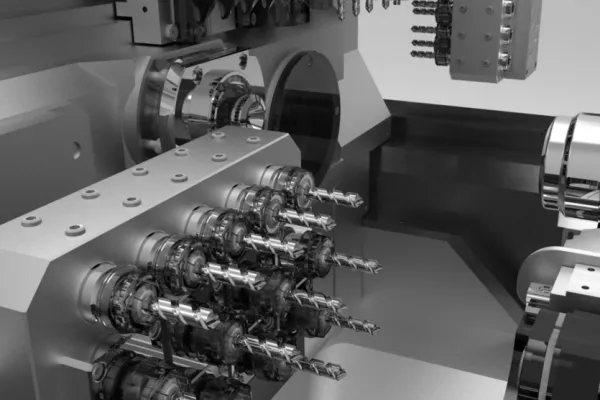

Scheming structure

The structure of the processing area is mainly composed of the main shaft (sub-spindle) and the tool structure.

1. Spindle: It can carry out multiple feeding tasks, and can move in any direction according to the Z1 axis and C1 axis when it is hard.

2. Sub-spindle: When moving, it can move according to the directions of Z2, X2 and C2 axis. It can be changed and moved at will in various directions. The main function is to assist the main shaft for processing and material splicing. There are some products. Subsequent processing requires processing on the corresponding tool post on the secondary shaft. During processing, a special control channel separate from the main shaft is used, which can achieve complementary intervention with the main shaft. In the actual application process, both axes need to be processed at the same time. Such an operation mode can effectively shorten the overall processing efficiency of the product.

3. Tool holder: It is divided into four parts, mainly the turning tool, the side power head, the end face and the fixed seat in the direction of the counter shaft end face.